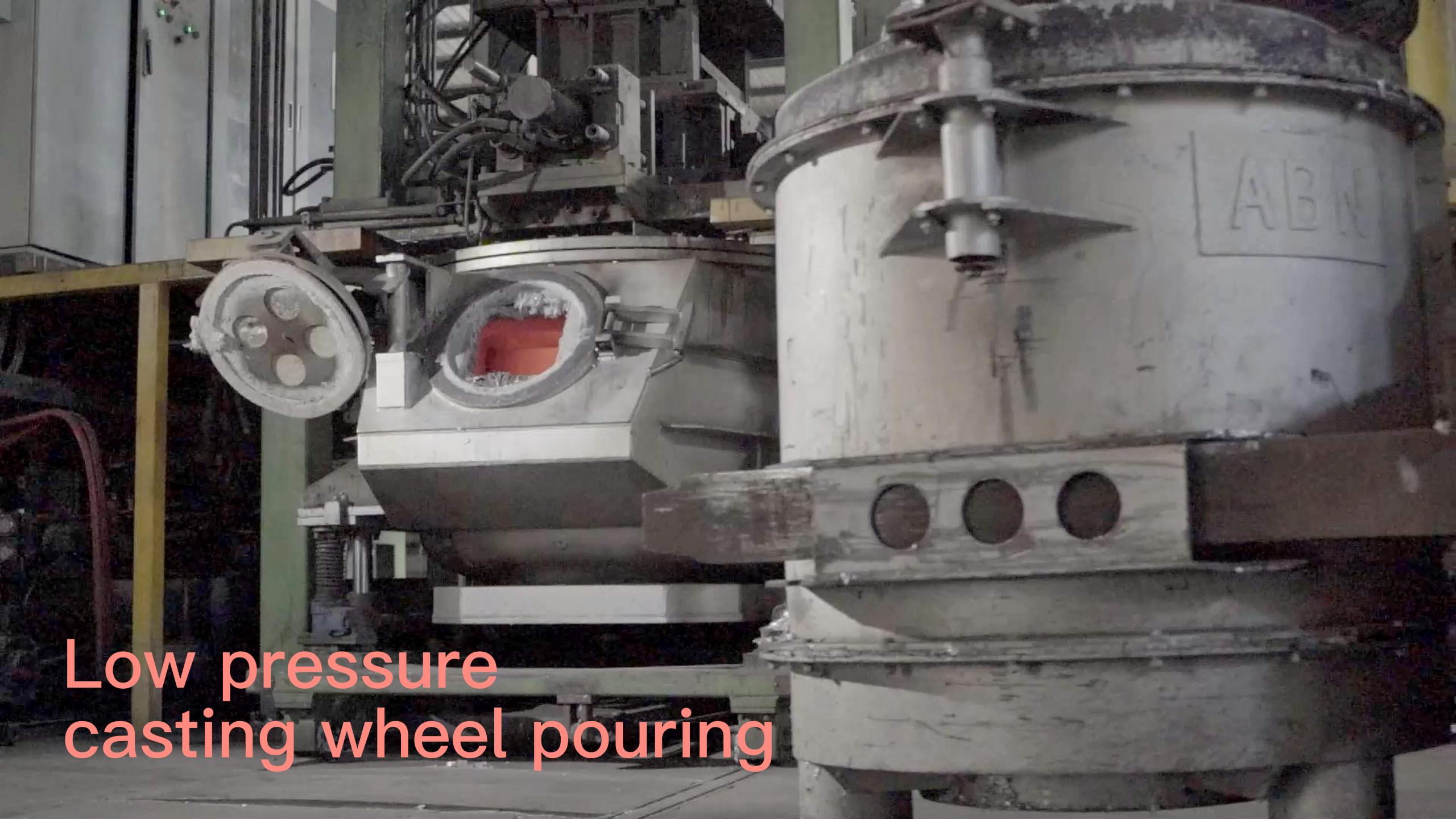

JWHEEL Low Pressure Casting Wheel Pouring.

The aluminum water, which is about 700℃ or above and well mixed, is transported to the machine with special equipment and safely poured into the low-pressure casting equipment. The transportation process needs to pay attention to the safety of personnel and the operation of the machine to make sure it is 100% safe before operation.

We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

The company adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers. The company also sets up a professional team for new product development, design, mold manufacturing, trial production, testing and inspection to provide customers with technical development and support services.

The formula has perfect testing equipment, including material testing machine, hardness tester, solid aluminum alloy containing slag quantitative tester, X-ray diffractometer, bending fatigue tester, radial fatigue tester, biaxial fatigue tester, 13° impact tester, 30°/90° impact tester, salt spray test chamber, humidity and heat test chamber, etc., which can carry out the four major testing areas of wheels (dimensional testing, alloy material performance, reliability and safety, coating and We have formed a complete testing system from the incoming inspection of raw materials to the factory inspection of finished products, and our testing capabilities range from material and performance to dimensional and impact and fatigue testing, and then to the testing of the coating performance of finished wheels.

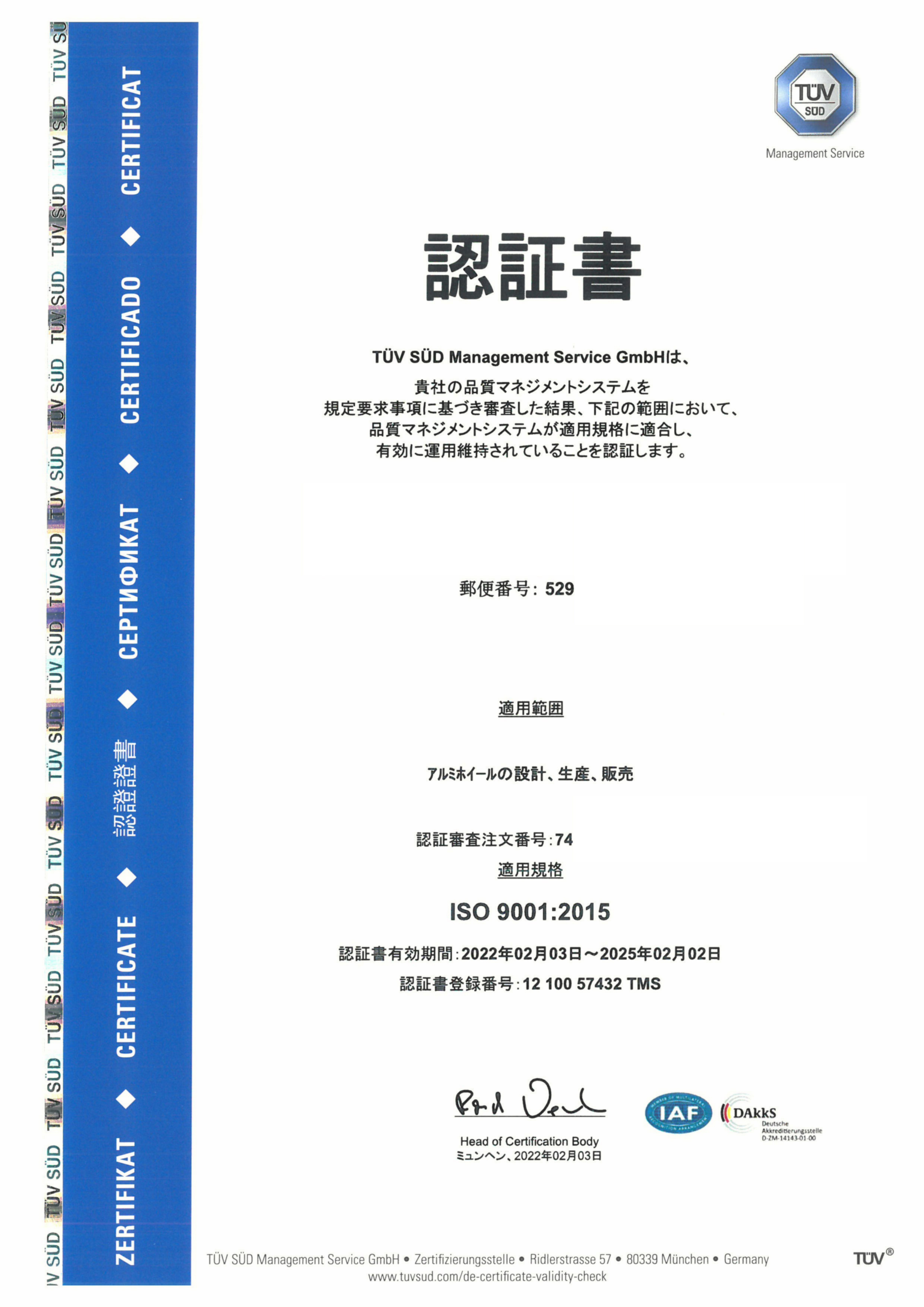

The company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association certification (laboratory certification).

Contact Us

Leave A Message

Recommended